The Many Uses of Refractory Ceramic Fiber

Refractory ceramic fiber products have become invaluable in businesses that require operations and manufacturing processes that generate extremely high temperatures. They’re used both in direct contact with fire, and as insulation to retain heat in one place.

Ceramic Fiber has a variety of uses and is a favorite in the manufacturing and automotive industries.

Click To Tweet

Refractory Ceramic Fiber

Refractory ceramic fibers have heat-resistant properties and are an excellent material for heat-resistant insulation. Ceramic fiber comes in several different forms and can be used for numerous applications. Here are some fast facts about refractory ceramic fiber:

Traits

- Extremely resistant to chemicals.

- Typically used in temperatures from 1100°F to 2600°F.

- Also known as High-Temperature Insulation Wool (HTIW), Kaowool, or Ceramic Fiber Wool (CFW) depending on chemical makeup.

- Made of calcined kaolin clay OR a combination of Alumina and Silica, with small amounts of Zirconia in some.

- Can be shaped and bonded into a variety of shapes and textures.

Types & Uses

- Ceramic Fiber Blanket – Used in direct exposure to flames.

- Cloth – Commonly used in architecture for fire doors, furnace & insulation.

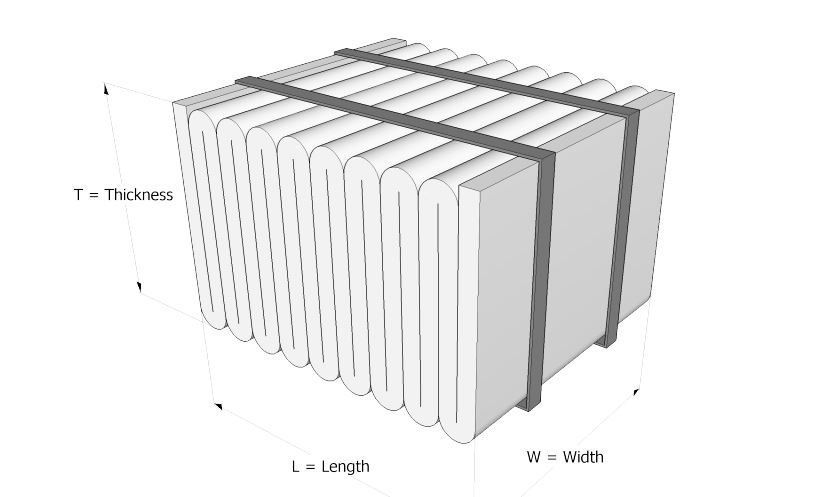

- Ceramic Fiber Module – A ceramic fiber blanket that is accordion folded and compressed to a required density.

- Rope – Ceramic fiber rope can be used to support or attach various heat-resistant structures.

- Paper – Ideal for various insulation purposes, such as covering gaskets to hold in high temperatures.

- Additive – Common in various architectural structures, such as heat-resistant roofing or walls.

A Versatile Product

Because refractory ceramic fiber can take such a variety of forms, it is frequently used in many different ways. From brake pads to furnace insulation, they’ve become an invaluable tool in high heat situations and processes.

Contact Us for more information about refractory ceramic fiber modules or our other refractory materials.

The post The Many Uses of Refractory Ceramic Fiber appeared first on Refractory Materials, Precast Shapes, and Custom Solutions.